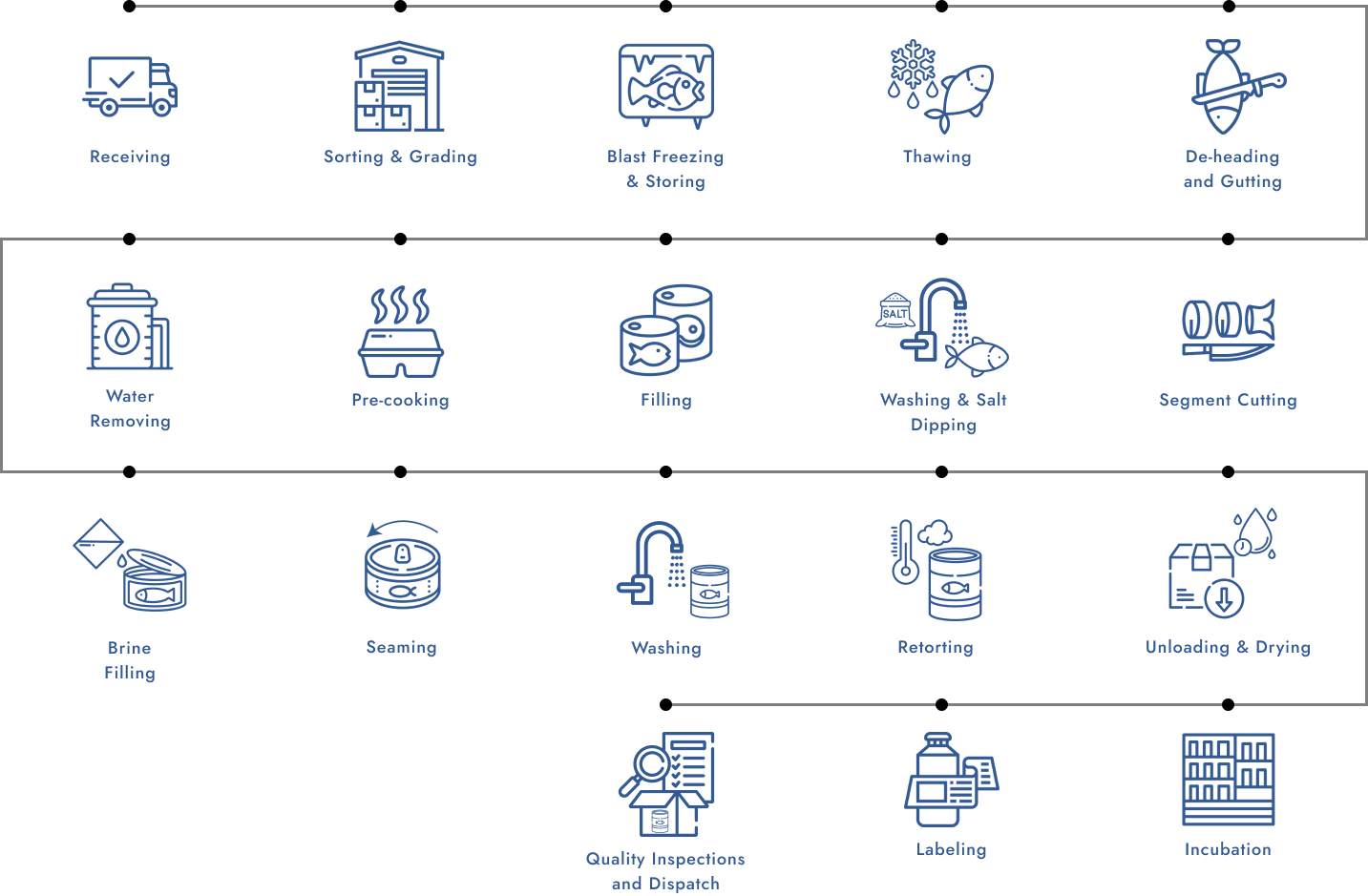

Where quality and freshness meet in every bite! From receiving to final inspection, our meticulous process ensures each can delivers the finest seafood experience. Trust PRF Seafood for premium canned seafood straight from the ocean to your table.

Where quality and freshness meet in every bite! From receiving to final inspection, our meticulous process ensures each can delivers the finest seafood experience. Trust PRF Seafood for premium canned seafood straight from the ocean to your table.

Receiving

Freshly caught fish received mainly from the down south area under chilled conditions by the selected suppliers. Suppliers must use refer trucks for the transportation of fish and they should be stored with ice.

01

Sorting & Grading

The received fish is sorted by our well-trained staff under the quality division of PRF seafood, as per the criteria given by the quality division. This is the only canned fish factory in Sri Lanka that has a separate fish unloading area before further processing.

02

Blast Freezing & Storing

The sorted fish blast frees and is stored in a -18C cooled room with the day. The capacity of the blast freezer is 24 tons per day and having a cold room capacity for 100 tons of fish.

03

Thawing

Fish received from the cold rooms for the production process will thaw in the chill room.

04

De-heading & Gutting

Thawed fish de-heading and gutting before cutting for segments by well trained staff

05

Segment Cutting

The de-headed and gutted fish are cut into segments as per the size requirement for can filling.

06

Washing & Salt Dipping

Fish segments are thoroughly washed to remove particles and dipped in salt water for preservation.

07

Fill into the Cans

Salt-dipped fish segments were filled into the cans as per the instruction given by the quality control division by the well-trained staff.

08

Precooking

The fish pre-cooking process will be carried in steam to remove natural oil and other strong flavors.

Water Removing

The water filled into the cans in the pre-cooking process will be removed automatically in the canning line to remove particles of fish and oil.

Brine filling

The brine solution fills into the cans in the line automatically.

Seaming

Brine-filled can lids sealed by fully auto can seamer with the speed of 50 to 250 cans per minute.

Washing

The lid-sealed canned wash in the can line automatically.

Retorting

The cans retorted by fully auto retort as per the parameters given by the PRF quality control division.

Unloading & Drying

The retorted canes dried to prevent corrosion.

Incubation

Tests sterilization effectiveness by incubating cans to detect any remaining microorganisms.

Labeling

Applies labels with key product details to meet regulatory requirements.

Quality Inspections and Dispatch

Conducts final safety and quality checks before dispatch.